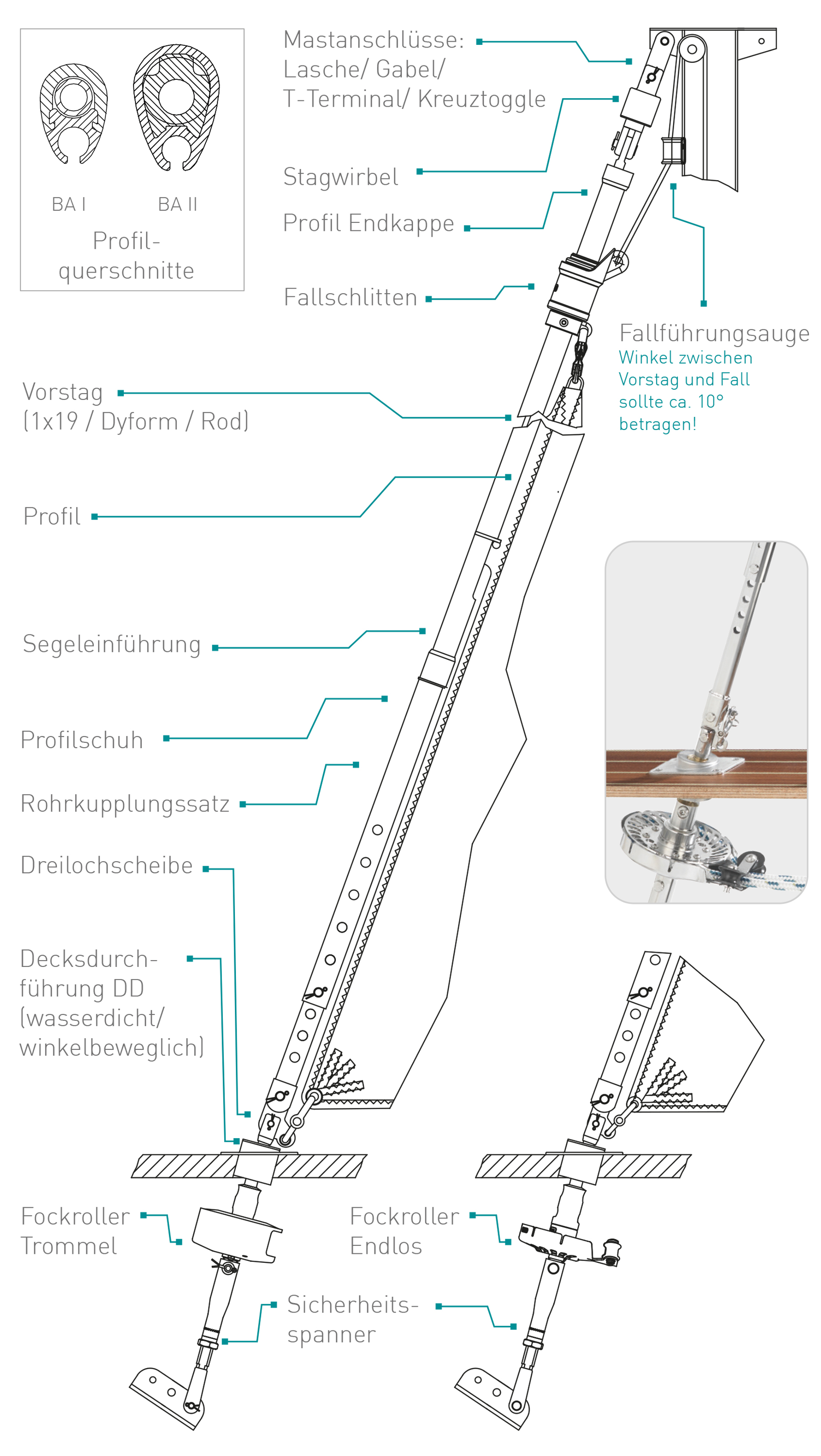

Für die Verbindung zwischen Stagwirbel und Mast stehen Laschen, Gabeln und T-Togglen zur Auswahl. Der Wirbel muss sich frei in Zugrichtung des Vorstages einstellen können, ohne das er am Mast streift oder das Fall beeinträchtigt wird.

D1 systems

Reefing systems with profiled forestay

Rotating stay

Endless line or drum furler

Mounting below deck

Reefing system with profiled forestay (mounted below deck)

This reefing system with watertight deck lead-through is used both on classic yachts in order to largely preserve the traditional appearance despite modern technology, as well as in regattas to enable an attachment point for the sail tack close to the deck. Thanks to the angular flexibility of the watertight deck passage on both sides, misalignments caused by installation tolerances below deck and different forestay angles are compensated for. These angles vary due to the mast drop and sag of the forestay.

The sail area can be continuously reduced with reefing systems, provided the sail is suitable for this due to its cloth weight and workmanship. Sails with staysails can be reworked by sewing on a luff tape, while larger sails with a deep cut (profile) must be made reefable by doubling up close to the luff. The forestay length and therefore the mast drop can be adjusted independently of the profile length using the tube coupling set. An aluminium profile located above the forestay wire makes it possible to insert the luff into the groove and push it through with the halyard swivel. Depending on the size, the profile sections are available in 2-metre lengths for shipping and can be easily replaced in the event of damage.

Advantages:

- Safe and fast reefing directly from the cockpit

- Simple and quick sail change (no need to attach and detach the staysail riders)

- Safe sail change (the halyard always remains attached to the forestay via the halyard swivel when changing sails)

- Lowest possible attachment point for the sail halyard

- Improved inflow (no sagging of the luff as with stay riders)

- Compensation for misalignment

- Transmission of the forestay forces to the jib

D1 below deck Variants

Endless lines jib furler

Endless line jib furlers are ideal for easy furling and reefing of sails such as large genoas, small jibs or light wind sails such as Code0 and gennakers. BARTELS specialises in the manufacture of robust, durable and functional endless line jib furlers. These furlers are made entirely of stainless steel and feature smooth-running ball bearings that function smoothly even under heavy loads. The ball bearings are multiply protected against water and dust. The endless line can be removed in a few simple steps and can be used in 8 mm or 10 mm diameter. The non-slip rope pulley enables use in both rolling directions, and the lead-in angle can be individually adjusted in 12 positions. A toggle ensures flexibility during assembly and sailing.

Drum jib furler

Drum furlers are the tried and tested classic for jib furling systems. They enable effortless winding and unwinding of sails or lines, with only one line having to be fed into the cockpit. Our jib furlers are made entirely of high-quality stainless steel, which guarantees their durability and robustness. BARTELS specialises in the production of functional, durable drum furlers. The furlers have smooth-running ball bearings that operate without any problems even under heavy loads and are particularly reliable thanks to multiple protection against water and dust. The lead-in angle of the line can be individually adjusted in 12 positions to ensure optimum functionality. A toggle below the jib furler also ensures flexibility during assembly and while sailing.

Deck bushing watertight and angular movable

The DD deck passage is an innovative solution in boat building that can be moved independently at an angle on both sides and is completely watertight. The jib furler is mounted invisibly below deck, allowing the sail to be attached particularly close to the deck. This type of deck passage is particularly popular with classic and high-quality yachts. The DD deck passage is available in four different sizes and has proven itself in small dinghies weighing just a few hundred kilograms as well as in large yachts such as the 12mR class weighing over 20 tonnes. This versatility and reliability make the DD deck grommet a favourite choice for demanding sailors.

Stage vortex

Stay swivels are the counterpart to jib furlers. The forestay to which the sail is attached rotates in stay furlers. Heavy-duty, smooth-running ball bearings are integrated into jib furlers and stay swivels. The static and dynamic forestay load is transmitted from the jib furler via the ball bearings of the jib furler, along the forestay wire and via the bearings of the stay swivel to the mast connection. The ball bearings are orientated to the breaking load of the forestay wire and are available in sizes from 3 to 12 mm. The sail head is fixed via a halyard swivel which is attached to the rotating forestay. This halyard swivel also contains a smooth-running ball bearing that decouples the rotation of the forestay and halyard so that the halyard is not wrapped around the forestay. The forestay wire is connected to the lower end of the swivel using an eye terminal. If a halyard swivel with clutch is used, the clutch rod is attached directly to the underside of the swivel via a lug.

halyard swivel for profile forestay

Halyard swivels are used in furling and reefing systems when the halyard of the headsail is to be guided in the mast. They prevent the halyard from wrapping around the forestay when the sail is furled by decoupling the rotation of the halyard. Halyard swivels slide over a profile insert on the forestay profile that is adapted to the profile geometry. The rotary movement of the profile is transferred to the attachment point of the sail head, whereby the sail is furled parallel to the forestay at the neck and head, preventing the sail from billowing in the head area.

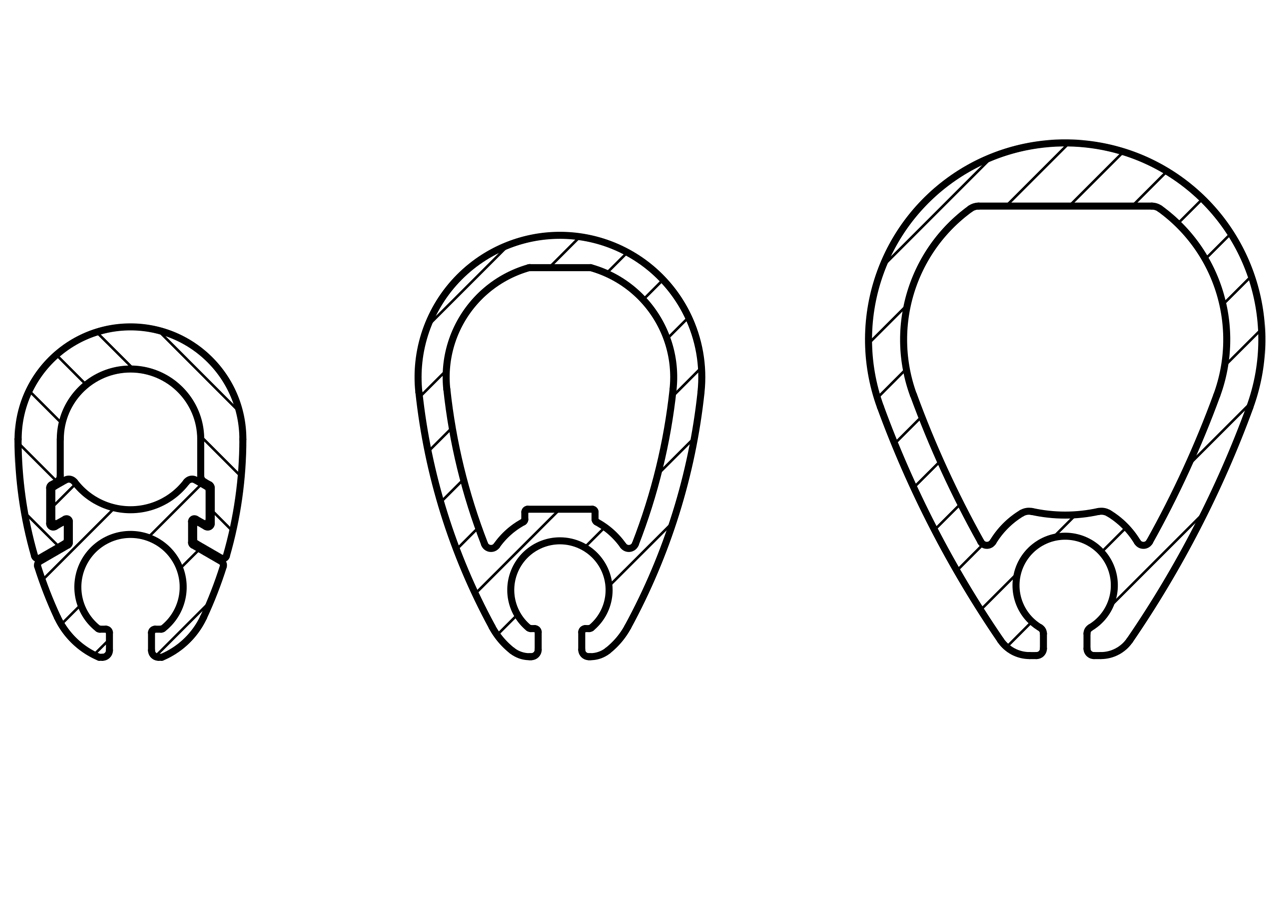

BARTELS profile forestages

BARTELS profile forestays are made from high-quality aluminium profile segments that are joined together to form a stable forestay profile and installed around the forestay wire. The wire runs inside the profile and forms the central axis for the furling and reefing process. In D1 systems, the forestay wire rotates together with the extrusion, whereas in D2 systems the wire remains fixed and only the extrusion rotates. The sail is guided in the single, specially developed keder groove via a leech tape.

BARTELS forestay profiles are available in three sizes and are characterised by their unique design with only one keder groove - a concept that makes it much easier to change sails, as two keder grooves would prevent the halyard swivels from passing through. This solution was chosen over 40 years ago in order to optimise the aerodynamic shape and ensure an almost vortex-free flow of the sail. Our forestay profiles therefore guarantee a smooth furling and reefing process that also fulfils high performance requirements.