Bedienung über eine Endlosleine welche unter Deck bis ins Cockpit geführt wird.

C1 & C2 systems

with endless line or drum reel

Can be mounted on and below deck

halyard guided on/in the mast

halyard swivels with and without entrainment

Stagreiter sail furling system

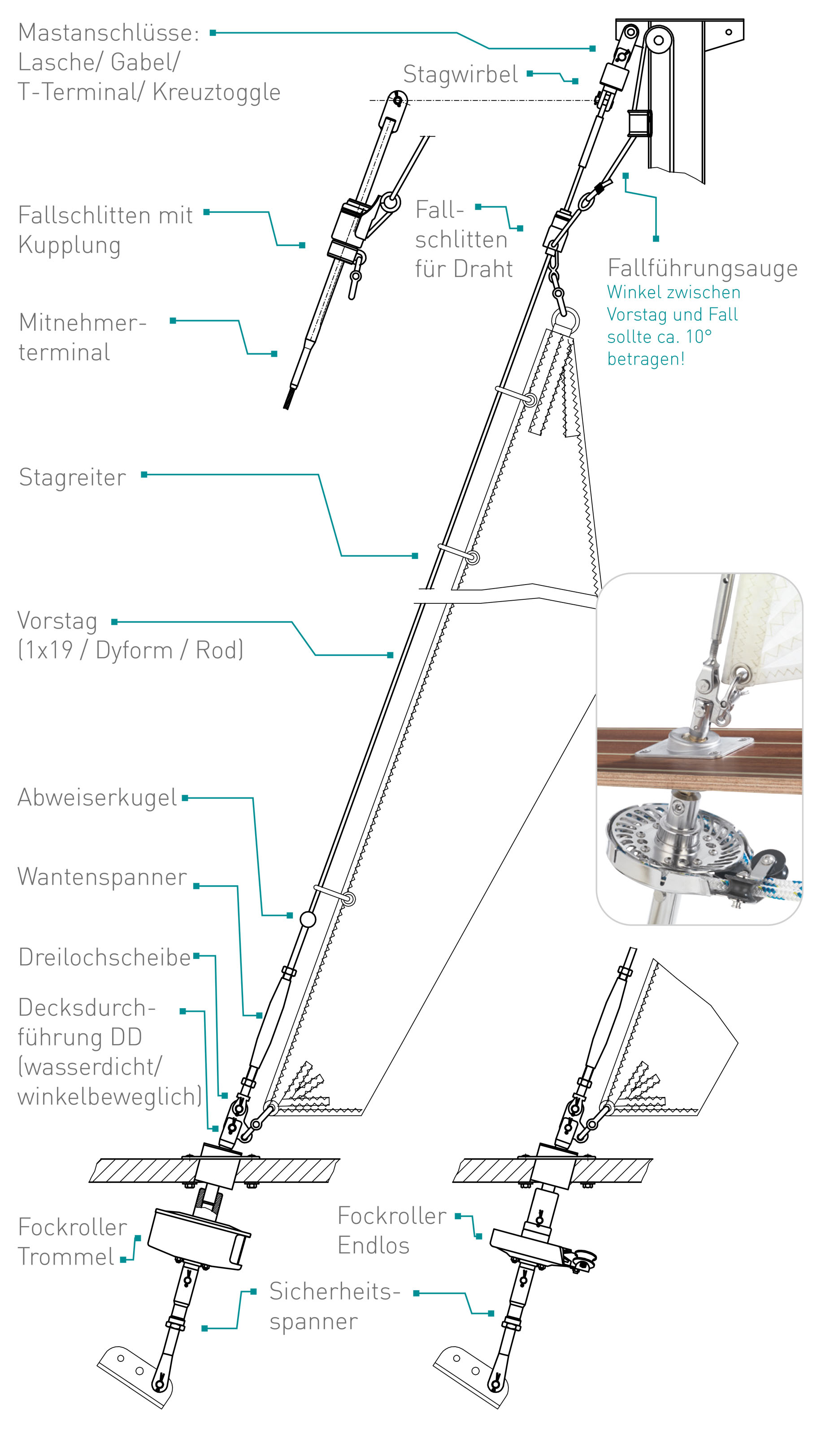

This type of system with a watertight deck passage is mainly used on classic yachts in order to largely preserve the traditional appearance despite modern technology. The below-deck installation of furling systems is also an advantage in regattas, as it allows the forestay to be attached close to the deck if the class regulations permit a furling system. The furling jib systems with halyard swivels for wire forestays are specially designed for the complete furling of a headsail with stays. However, reefing is not possible as the wire forestay is unsuitable as a winding core; the sail would become tangled and damaged in this case. From a forestay length of 8 metres, we recommend the use of a halyard swivel with clutch and towing terminal.

Thanks to the two-sided angular movement of the watertight deck passage, misalignments caused both by installation tolerances below deck and by different forestay angles are compensated for. These angles can be influenced by varying mast drop and sag of the forestay. In the upper end position, the halyard swivel engages securely in the longitudinal groove of the clew terminal, which also rotates the sail head. This prevents the furled sail from being blown up in the head area in strong winds.

Advantages:

- Safe and fast furling directly from the cockpit

- Continued use of sails with staysails

- Preservation of the yacht's classic appearance

- Safe sail change (the halyard always remains attached to the forestay via the halyard swivel when changing sails)

- Lowest possible attachment point for the sail tack

- Compensation for misalignment

- Direct transfer of the forestay forces to the jib

C1 & C2 Variants

Endless lines jib furler

Endless line jib furlers are ideal for easy furling and reefing of sails such as large genoas, small jibs or light wind sails such as Code0 and gennakers. BARTELS specialises in the manufacture of robust, durable and functional endless line jib furlers. These furlers are made entirely of stainless steel and feature smooth-running ball bearings that function smoothly even under heavy loads. The ball bearings are multiply protected against water and dust. The endless line can be removed in a few simple steps and can be used in 8 mm or 10 mm diameter. The non-slip rope pulley enables use in both rolling directions and the lead-in angle can be individually adjusted in 12 positions. A toggle ensures flexibility during assembly and sailing.

Drum jib furler

Drum furlers are the tried and tested classic for jib furling systems. They enable effortless winding and unwinding of sails or lines, with only one line having to be fed into the cockpit. Our jib furlers are made entirely of high-quality stainless steel, which guarantees their durability and robustness. BARTELS specialises in the production of functional, durable drum furlers. The furlers have smooth-running ball bearings that operate without any problems even under heavy loads and are particularly reliable thanks to multiple protection against water and dust. The lead-in angle of the line can be individually adjusted in 12 positions to ensure optimum functionality. A toggle below the jib furler also ensures flexibility during assembly and while sailing.

Deck bushing watertight and angular movable

The DD deck passage is an innovative solution in boat building that can be moved independently at an angle on both sides and is completely watertight. The jib furler is mounted invisibly below deck, allowing the sail to be attached particularly close to the deck. This type of deck passage is particularly popular with classic and high-quality yachts. The DD deck passage is available in four different sizes and has proven itself in small dinghies weighing just a few hundred kilograms as well as in large yachts such as the 12mR class weighing over 20 tonnes. This versatility and reliability make the DD deck grommet a favourite choice for demanding sailors.

Drop sleds with and without clutch

Halyard swivels are used in furling and reefing systems when the halyard of the headsail is to be guided in the mast. They prevent the halyard from wrapping around the forestay when the sail is furled by decoupling the rotation of the halyard. In stay rider furling systems, a simple halyard swivel is used up to a forestay length of 8 metres, in which only the sail tack is driven by the jib furler. From a forestay length of 8 metres, the use of a dome halyard swivel is recommended. This snaps onto the sail head and transmits the rotational movement from the forestay to the halyard swivel, whereby the neck and head are furled simultaneously and in parallel - reliably and without the sail twisting or billowing.

Stage vortex

Stay swivels are the counterpart to jib furlers. The forestay to which the sail is attached rotates in stay furlers. Heavy-duty, smooth-running ball bearings are integrated into jib furlers and stay swivels. The static and dynamic forestay load is transmitted from the jib furler via the ball bearings of the jib furler, along the forestay wire and via the bearings of the stay swivel to the mast connection. The ball bearings are orientated to the breaking load of the forestay wire and are available in sizes from 3 to 12 mm. The sail head is fixed via a halyard swivel that is attached to the rotating forestay. This halyard swivel also contains a smooth-running ball bearing that decouples the rotation of the forestay and halyard so that the halyard is not wrapped around the forestay. The forestay wire is connected to the lower end of the swivel using an eye terminal. If a halyard swivel with clutch is used, the clutch rod is attached directly to the underside of the swivel via a lug.